At Kirkstall Precision Engineering, we value our relationships with clients, suppliers and employees highly, so much so that we consider them all to be a part of the KPE family and an integral part of our continuing success.

One of our longstanding suppliers and customers, and a true partner to KPE, is Industrial Designer Gary Fenton. He has worked in partnership with KPE for over 20 years, firstly through DePuy International and then through his own consultancy company, Formative Design and medical tray supplier, Fentray.

Flexible across a wide range of industries.

Kirkstall’s relationship with Gary predominantly involves the design and manufacture of medical devices for use in both animal and human surgery. Prototypes and large-scale roll outs of products are developed for companies such as Orthomed and Jointmedica. Gary also has extensive experience in creating designs for automotive components and consumer products, such as award-winning kitchen knives.

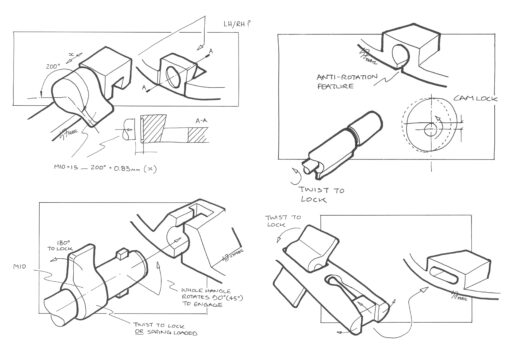

Talking about his close association with Kirkstall, Gary commented: “My relationship with Kirkstall is one built on mutual respect and they are a company who really pull out all the stops for me. For example, a surgeon could contact me with an idea for a device to get behind a bone and drill a 3mm hole. I then work up some concepts and present initial sketches to clarify the design inputs. After consultation, I work up the detailed designs on the computer using Solidworks (CAD). I then send my designs to the team at Kirkstall and they’ll work with me to fine-tune the details to ensure it is viable, both from a working prototype and a mass production run.”

Collaboration is the key to this long-standing relationship

Collaboration is highly valued by both Kirkstall and Gary, especially when it comes to developing new products. Fentray supplies innovative instrument trays to the veterinary market. The Fentray range of products are custom-machined surgical instrument trays with innovative lids that were designed by Gary and produced by Kirkstall.

Talking about the creation of Fentray, Kirkstall’s MD Adam Thornton commented that: “Like Gary, we get a lot of surgical instrument requests, but strangely enough there’s no true dedicated place for these instruments to be held. Gary came to us with the idea for Fentray, providing us with 3D CAD models that we then produced as working prototypes together with Gary’s 3D plastic printing capability. It’s just one of the many projects we have worked on together over the years.”

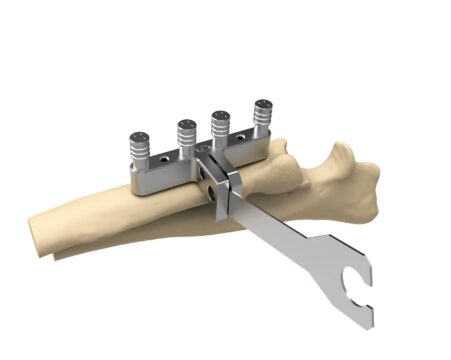

The canine cruciate repair system for Orthomed

One such project that both Gary and KPE have worked on together, for Orthomed, is the canine cruciate repair system (MMP). This device uses a wedge-shaped implant of titanium OrthoFoam™ which both defines the degree of advancement of the tibial tuberosity and holds the bone in place. This enables bony ingrowth that provides a permanent biomechanically robust fixation.

Jointmedica complete hip replacement system

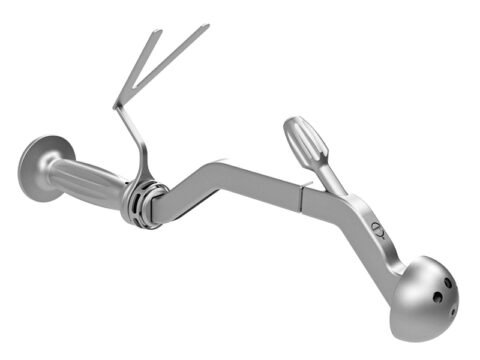

Another project that Kirkstall has worked on with Gary is a complete hip replacement system, which has around 20 to 30 instruments. One device, an Introducer, enables the hip replacement to be impacted into place. This device is quite complex and has around seven or eight moving parts. The degree of flexibility in the fitting and assembly of the instrument was key to the functionality of the device. It was a project that showed a true collaborative effort between both parties.

To find out more about Gary and his work, please see the links and gallery below. To discuss how together we can help you design and create a wide range of devices, simply get in touch by emailing: adam@kirkstallpreciison.co.uk

Formative Design: http://formdes.net/

Fentray: http://fentray.yolasite.com/